UV roll-to-roll machine and Eco-solvent printer machine are two different printing technology equipment. Although there are many similarities, there are also some obvious differences.

1. Printing materials:

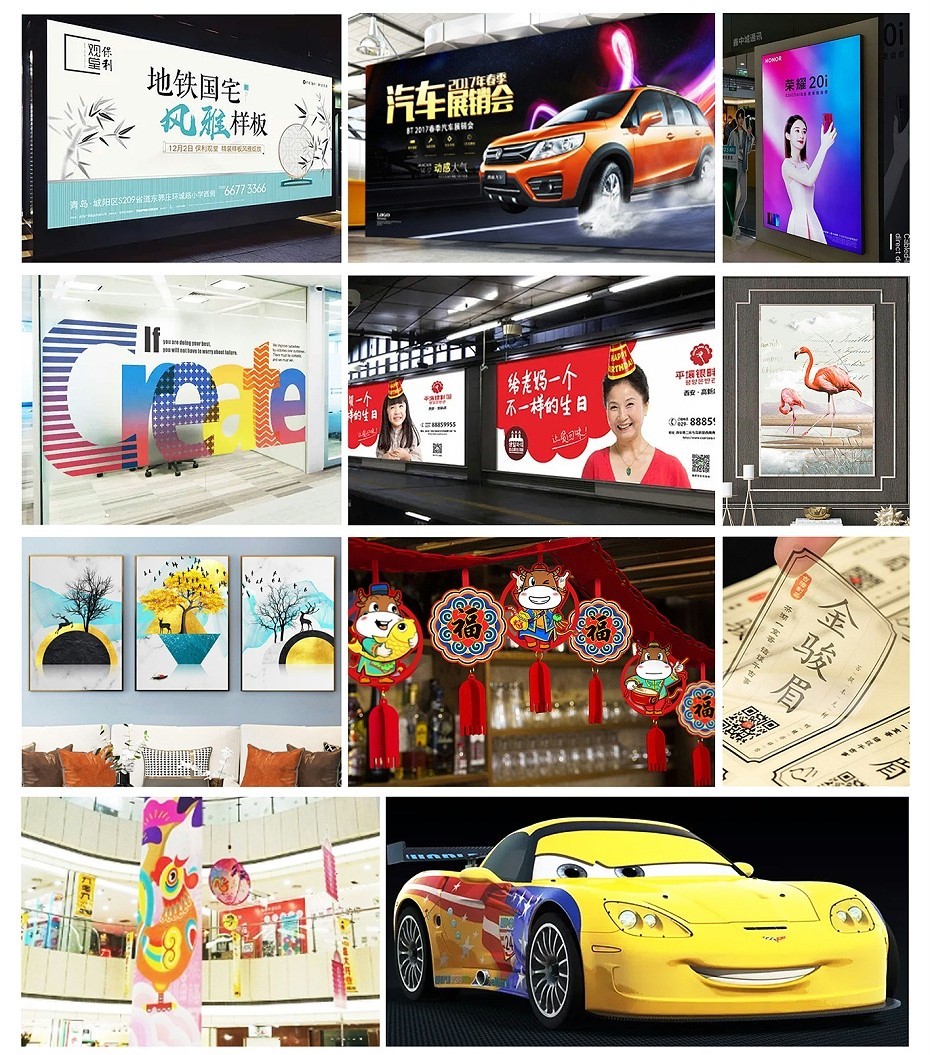

UV roll-to-roll machine is mainly used to print large-size roll materials, such as billboards, banners, etc., while Eco-solvent printer machine is mainly used to print flat materials, such as posters, business cards, flyers, etc.

2. Printing technology

The printing technology of the two is different. UV roll-to-roll machine uses ultraviolet curing ink, which is quickly cured on the printing material by ultraviolet irradiation. Eco-solvent printer machine uses inkjet printing technology, and the ink is sprayed onto the printing material through the nozzle and dried by hot air or ultraviolet light.

3. Speed and resolution

UV roll-to-roll machine has higher printing speed and higher resolution than Eco-solvent printer. UV roll-to-roll machine can achieve larger size printing, and can also print on printing media of different materials, such as cloth, plastic, metal, etc.

4. Printing effect

UV roll-to-roll machine uses ultraviolet curing ink, and the printed pattern is bright, durable and high gloss. The printing results of Eco-solvent printer printing machines are closer to traditional color printing, which can present delicate colors and gradient effects.

In summary, there are obvious differences between UV roll-to-roll machines and Eco-solvent printer printing machines in terms of printing materials, printing technology, printing speed and resolution, and printing effects. The choice of which device to use depends on specific needs and printing objects.