DTF printer is a technology applied in the clothing industry, which means high-temperature transfer printing is applied to fabrics. The required patterns are designed on a computer, transmitted to a DTF printer for printing, and then passed through a shaking machine for powder coating and high-temperature curing. After that, they can be pressed onto clothes without the need for plate making, carving, waste disposal, or minimum order quantity. It achieves a true minimum order quantity and zero inventory, which is highly sought after by e-commerce owners and personalized customization factories.

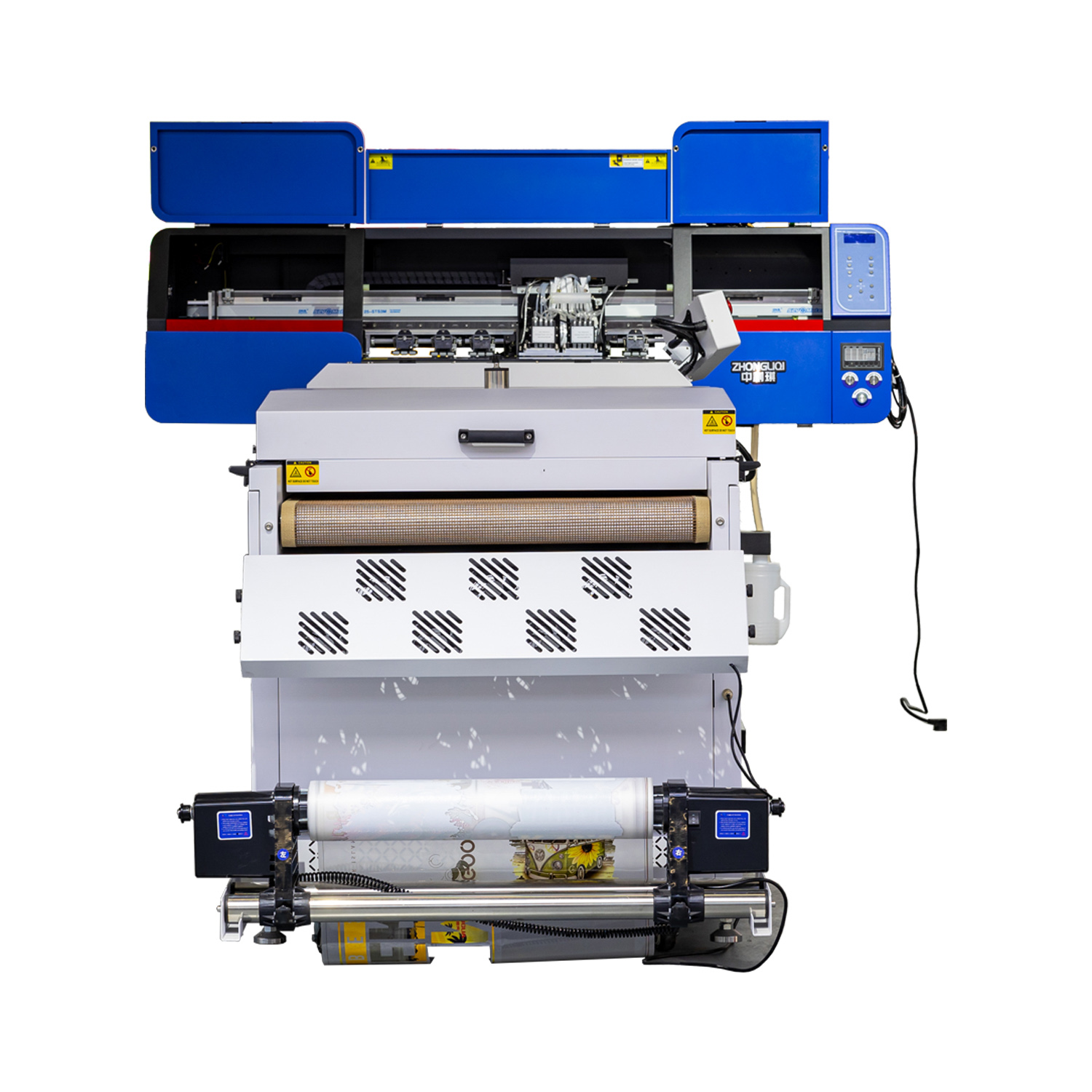

UVDTF printer is a new technology applied in the advertising industry. Unlike DTF, it has a simpler process. The required patterns are designed on the computer, transmitted to the UVDTF printer for printing, and then automatically coated with film. After printing, it can be used directly. Compared with DTF, there is no need for a shaking machine in hardware, and it does not require high temperature color fixation. It can be directly attached to the required items by hand or machine, and the effect is very bright and clear. There is also a protruding three-dimensional sense, and there is no minimum order quantity, achieving a true minimum order quantity and zero inventory. It is highly sought after by the old trend of gift customization.

The application differences between DTF and UVDTF:

DTF is mainly used in fabrics, and some cotton is also polyester. The most common T-shirts and hoodies are mainstream, as well as eco-friendly bags, pillows, aprons, advertising shirts, and cultural shirts. Hemp, denim, and mesh fabrics can also be pressed and ironed.

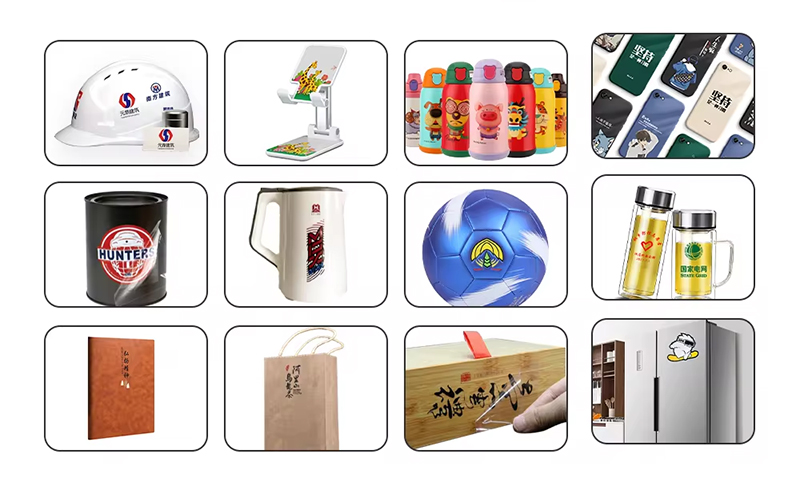

UVDTF is mainly applied to hard objects such as glass, metal, acrylic, wooden boards, ceramics, plastics, hard paper shells, etc. It can be pasted on flat, curved, and other surfaces. Typical representatives include tea boxes, wine bottles, cosmetics, labels, and other applications.