characteristic

(1)Good stability on the machine,clear dot reproduction,excellent ink-water balance. (2)Be able to adapt to the demand for middle-speed or high-speed printing. (3)During the normal condition, use the ink on the machine directly.

Ink color

CMYK+FY+FM

Scope of application

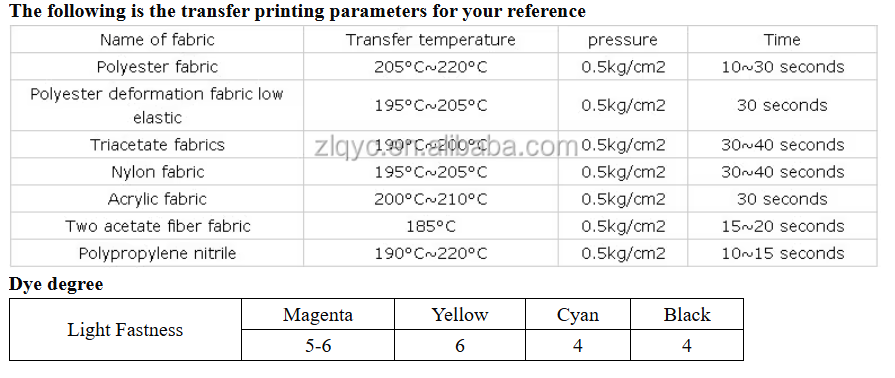

Polyester and other fabrics

Other details

Polyester fabric, Triacetate fabric, Nylon fabric, Acrylic fabric, Polypropylene nitrile.

Printing process

(1) Print the image on paper, and normal paper is ok. (2) Put the printed paper on substrate, such as polyester and nylon fabric. (3) Put the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will betransfer printed from paper onto the substrate.

For our sublimation offset ink, first print image on paper,second put the paper on fabric, and then press the paper with transfer machine. Under the temperature about 190°C-220°C, the ink on paper will become gas and go into fabric. So the image will be from paper to fabric.

Use Method

(1)Be able to adapt to the demand for middle-speed or high-speed printing.

(2)During the normal condition, use the ink on the machine directly.

(1)Good stability on the machine,clear dot reproduction,excellent ink-water balance.

(2)Be able to adapt to the demand for middle-speed or high-speed printing.

(3)During the normal condition, use the ink on the machine directly.

* No Crust

a.Granula size is less than 5 micron.

b.No crust in 7 days at normal temperature.

* Safety

Passed SGS,DGM,MSDS,totally environment-friendly.

Polyester fabric, Triacetate fabric, Nylon fabric, Acrylic fabric, Polypropylene nitrile.