characteristic

Printing advantages: The printed patterns are rich in layers, bright colors, ever-changing, small color difference, good reproducibility, the image will not fall off, crack and fade. The ink does not add any harmful substances to the body, and this one can not be skinned for a long time after opening the cover; different models of products can be developed according to the needs of unused customers, which can meet your target price.

Ink color

Megenta /Yellow/ Cyan /Black

Scope of application

Printing materials: double offset paper, coated paper, coated paper, offset paper, cardboard Scope of application: It is suitable for single-sheet paper feeding single-color machine, two-color or multi-color offset printing machine.

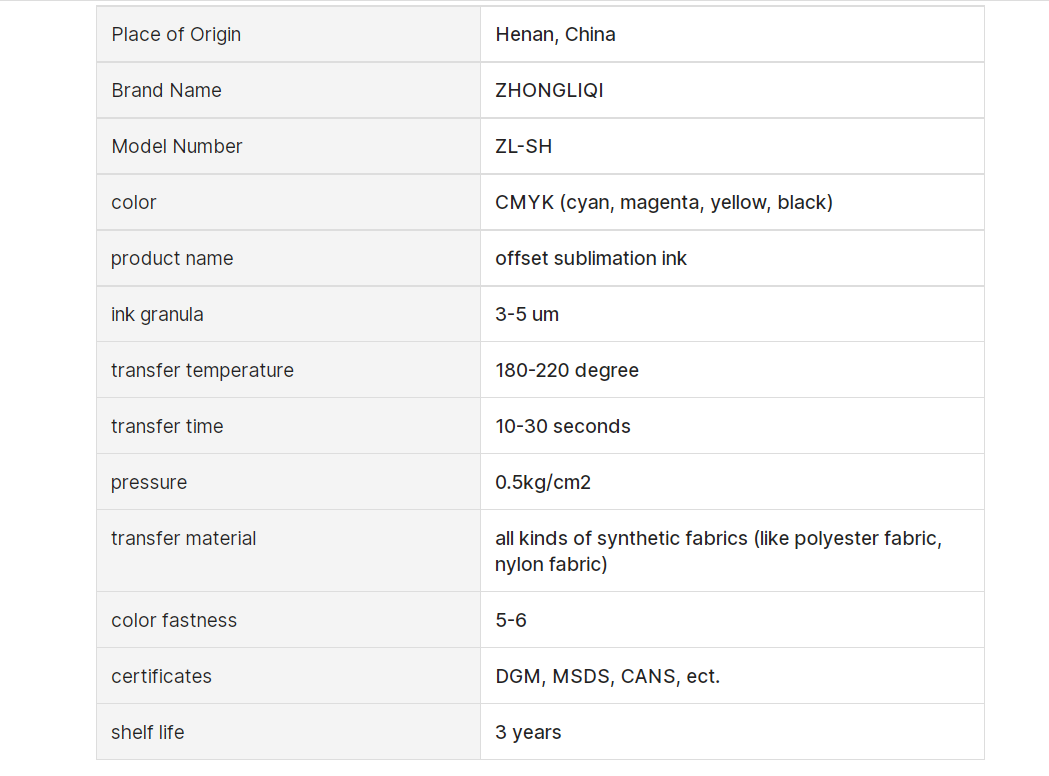

Technical specification

1KG/2KG/10KG

Other details

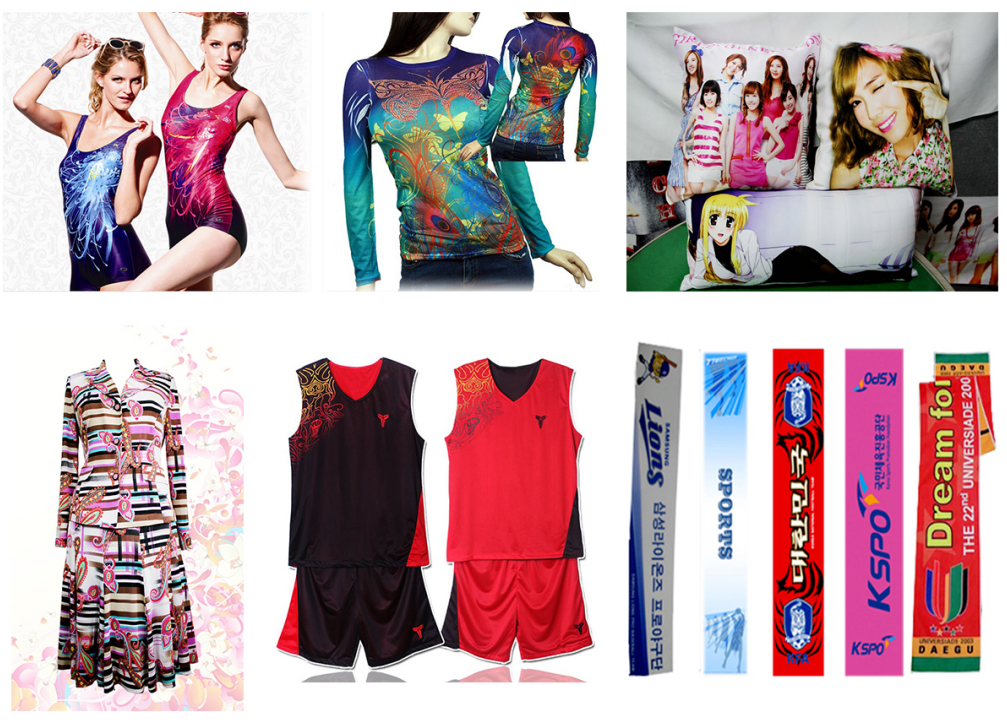

Applicable printing: textile printing, clothing printing, luggage printing, handicraft ornaments, etc.

Printing process

Offset sublimation ink is also called offset sublimation transfer ink, offset printing sublimation ink --- refers to the printing process of transferring sublimation sublimation ink to fabric through transfer paper.

Sublimation offset inks are designed to apply a mirror image onto paper for transfer to the final substrate.

The prints are transferred via heat and pressure onto most polyester or synthetic materials.

When first printed onto paper, sublimation inks appear to be weaker and duller than standard inks,

however when transferred onto suitable substrates, the dyes develop their true color strength and brilliance.

1. Excellent ink balance, clear dot restoration, fast coloring rate, and stable machine printing. 2. The patterns printed by this process are rich in layers, bright in color, varied in every way, and have small color differences. 3. The image will not peel, crack, or fade, and is wear-resistant and washable.

Usage and precautions 1. Under normal circumstances, it can be used directly on the computer; 2. Due to factors such as temperature, paper, printing speed, etc., adjustments can be made according to the following rules:; (1) Accelerate drying by adding a mixed desiccant at a dosage of 0-2%; (2) Equipped with a dedicated charge for indifference; (3) Adjust liquidity, use # 6 printing ink, dosage 0-5%; (4) Reduce paper viscosity while maintaining basic fluidity, and use a debonding agent with a dosage of 0-5%; (5) Simultaneously reducing viscosity and stickiness, 52-94 can be added at a dosage of 0-5%. (6) Under normal circumstances, it can be guaranteed that there will be no conjunctiva in the ink hopper of the printing machine for 36 hours.