characteristic

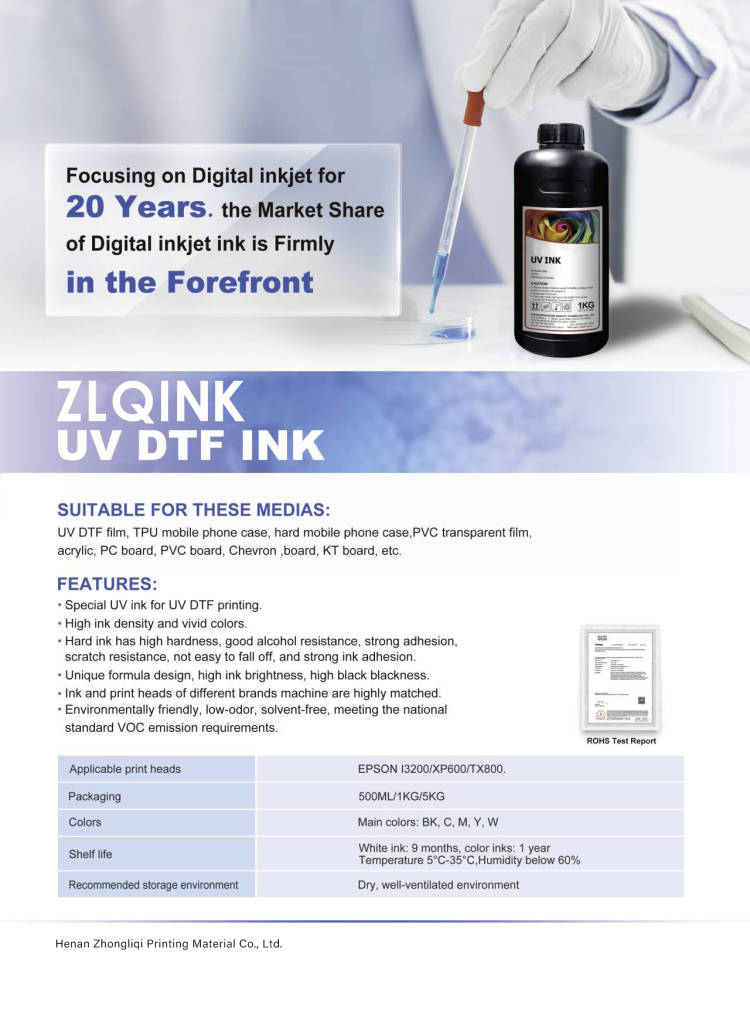

1.Unique formula design, perfect adhesion, no color change, no sticky hands 2.Outstanding low temperature resistance, no cracking after bending, elongation over 180% 3.High color concentration and vivid color performance 4.Eco-friendly, low smell, no toxic and volatile organic solvent, meet VOC emission standard

Ink color

K、C、M、Y、LC、LMW、G、R、OR、V

Suitable for printing head and model

Epson: 13200/S3200/DX5/DX7/XP600 Industrial print head: Kyocera, Richoh G5/G6, Konica 1024i/1024A, Toshiba, Seiko

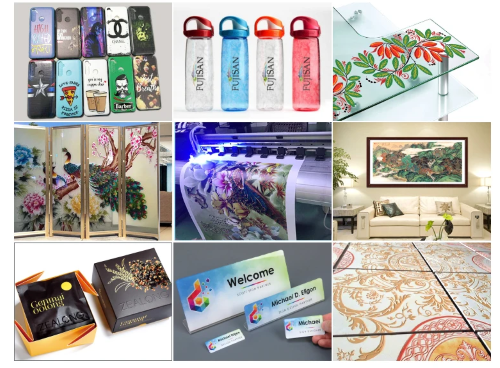

Scope of application

UV ink is suitable for fields such as printing, 3D printing, electronics, textiles, glass ceramics, etc.

Other details

Packaging specifications:2.5kg canned; 2kg vacuum bagged Shelf life: three years (can still be used after the shelf life if the technical indicators are qualified), store away from light and water

Printing process

When printing with UV ink, first fix the substrate (such as paper, plastic, etc.) on the equipment. Next, UV ink is coated onto it using inkjet heads or printing equipment to form patterned text. Subsequently, the substrate is fed into a UV curing device and irradiated with ultraviolet light, causing the photoinitiator in the ink to absorb light energy and trigger a polymerization reaction, allowing the ink to solidify instantly. Finally check and perform post-processing to complete the printing.

UV ink is an ink that uses light-curing resin as the main ingredient and needs to be cured by polymerization reaction initiated by ultraviolet light irradiation. It is liquid when uncured and quickly cross-linked into a solid state after being irradiated with UV light. It has the advantages of fast curing speed, environmental protection and no volatile, bright color, strong adhesion, scratch resistance and wear resistance, and is often used in printing and printing in packaging, advertising, decoration and other industries.

1.Unique formula design, perfect adhesion, no color change, no sticky hands

2.Outstanding low temperature resistance, no cracking after bending, elongation over 180%

3.High color concentration and vivid color performance

4.Eco-friendly, low smell, no toxic and volatile organic solvent, meet VOC emission standard

1.Advertising industry: used for making lightboxes, billboards, posters, etc., with bright and long-lasting colors.

2.Packaging printing: It can be printed on materials such as paper boxes, plastic packaging, labels, etc., to enhance the aesthetics and durability of packaging.

3.Decoration field: able to print decorative patterns on surfaces such as glass, tiles, wood, etc., to meet the needs of different decoration styles.