Background:

As one of the first domestic companies to focus on the research and development DTF inks, ZHONGLIQI adopts leading nano-grinding and dispersion technology to achieve nano-level precise control of titanium dioxide particles. This technology not only ensures that the particles can be evenly and stably dispersed in the aqueous solution, but also greatly improves the fluidity of the ink, ensuring the smoothness and efficiency of the printing process. At the same time, this innovative nano-scale dispersion also significantly improves the storage stability of the ink, bringing users a more reliable and efficient printing experience.

Advantages:

The process is simple, no hollowing is required, no waste is discharged, and it is green and environmentally friendly. By printing color and white paint ink on the digital heat transfer film combined with the powdering matching process, photo-quality effects can be easily achieved. The overall solution has low investment threshold, flexible inventory control, high efficiency and low cost.

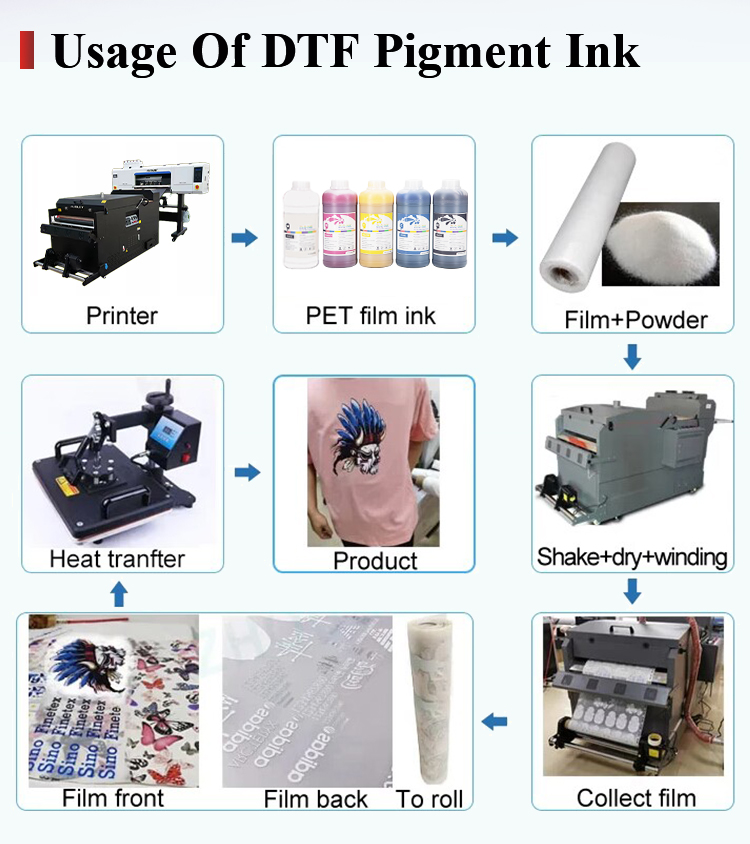

Process

① Print (digital inkjet printing, first color and then white) - ② Sprinkle powder and shake powder (hot melt powder) - ③ Dry (dry hot melt, temperature: 140-150℃; time: 3-5 minutes ) ④ heat press (transfer printing, temperature: 160-180°C; time: 10-20 seconds, pressure: appropriate).

Value

DTF ink enables high-speed printing, shortening the production cycle and improving efficiency. Vibrant colors, rich layered patterns, high color density and detail clarity provide visual impact. It is suitable for a variety of materials and irregular shapes to meet the needs of different industries. DTF ink is water-based , no VOCs, environmentally friendly, and high operator safety. The process is simple, reducing technical requirements and production errors.

Application

Related product