First :Introduction to UV-LED Ink

UV LED ink is developed on the basis of UV curable coatings. As a new type of environmentally friendly ink, it has the advantages of energy saving, no solvent emissions, no environmental pollution, high production efficiency, suitability for heat sensitive substrates, excellent printing performance, and low equipment investment. It has been highly valued by countries around the world and has been successfully applied in many fields such as coatings, inks, adhesives, printing plates, electronics industry, microfabrication, and rapid prototyping.

UVLED ink utilizes the radiation energy of ultraviolet light to excite the photoinitiator in liquid ultraviolet materials into free radicals or cations, thereby triggering a chemical reaction between the unsaturated double bonds in the ultraviolet material and forming a cured bulk structure. It fully complies with the "3E principle". The so-called 3E, which stands for Energy, saves energy and does not require heating of the substrate in ultraviolet light. Generally, UV curing is 1/5 of thermal curing; Ecological environment protection, UV curing materials do not contain or only contain a small amount of solvents, and the energy used for UV curing is electricity, without fuel or gas, and without CO2 production. Therefore, UV curing is known as a "green technology"; Economy, Economy, compact UV curing equipment, assembly line production, fast processing speed, thus saving space and high labor productivity. UV and curing processes ensure thinner film layers and excellent performance, reducing raw material consumption and helping to lower economic costs.

The UVLED ink printing process has been widely used in various fields such as cosmetics packaging, food packaging, toy packaging, foam packaging, high-end commercial printing, and products with high gloss requirements. UVLED ink has been widely used in various printing fields such as offset printing, embossing, flexographic printing, gravure printing, screen printing, and inkjet printing.

UVLED ink is mainly composed of photopolymer resin (photoactive oligomer), reactive diluent (diluent monomer), photoinitiator, coloring agent, additives, etc.

Second:Features

1. Flexible UV ink:Good low temperature resistance. does not crack when bent. and has a stretch rate of over 180%.

2. Hybird UV ink:Compliant with neutral ink standards,meet the printing needs of soft and rigid media.

3. Rigid UV ink:High hardness,the surface of the material is not easy to be scratched after printing.

Third:Applicable print heads

EPSON T3200/ I3200/ S3200/ F1440/ L1440, KYOCERA KJ-4A, RICOH G5/ G6, FUJIFILM SAMBA/ SG 1024, KONICA1024i, SEIKO 1024GS, etc.

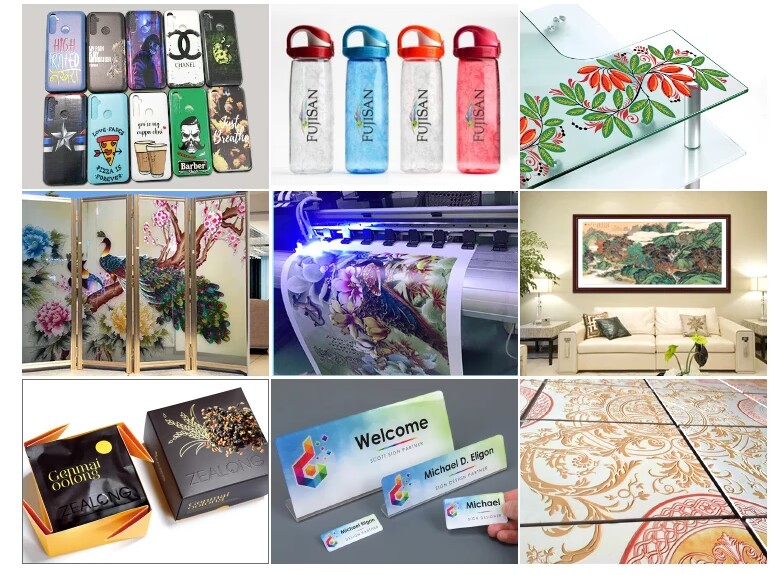

Fourth:Application

Flexible ink suitable media:Leather,Soft film,Car sticker, Wallpaper, Knife scraping cloth,3P cloth,etc.

Hybird ink suitable media:Leather,Soft film,Car sticker,Wallpaper, Knife scraping cloth, 3P cloth,TPU mobile phone case, Hard mobile phone case, PVC transparent film, Acrylic, PC board, PVC board, Chevron board, KT board, etc

Rigid ink suitable media:Acrylic, PC & PVC board, Chevronboard, KT board, Metal(with coating),Glass(with coating) etc

Related product recommendation