What is a UV printer?

A UV printer is a machine that can perform UV printing. UV "means ultraviolet light, and" UV printing "refers to UV curing printing, which is essentially a type of piezoelectric inkjet printing. The drying principle of printing is that when the ultraviolet light emitted by the LED cold light source reacts with the air, the UV ink is in the UV curing agent, and this reaction causes the pigment molecules in the UV ink to solidify on the surface of the material, thus completing the printing action.

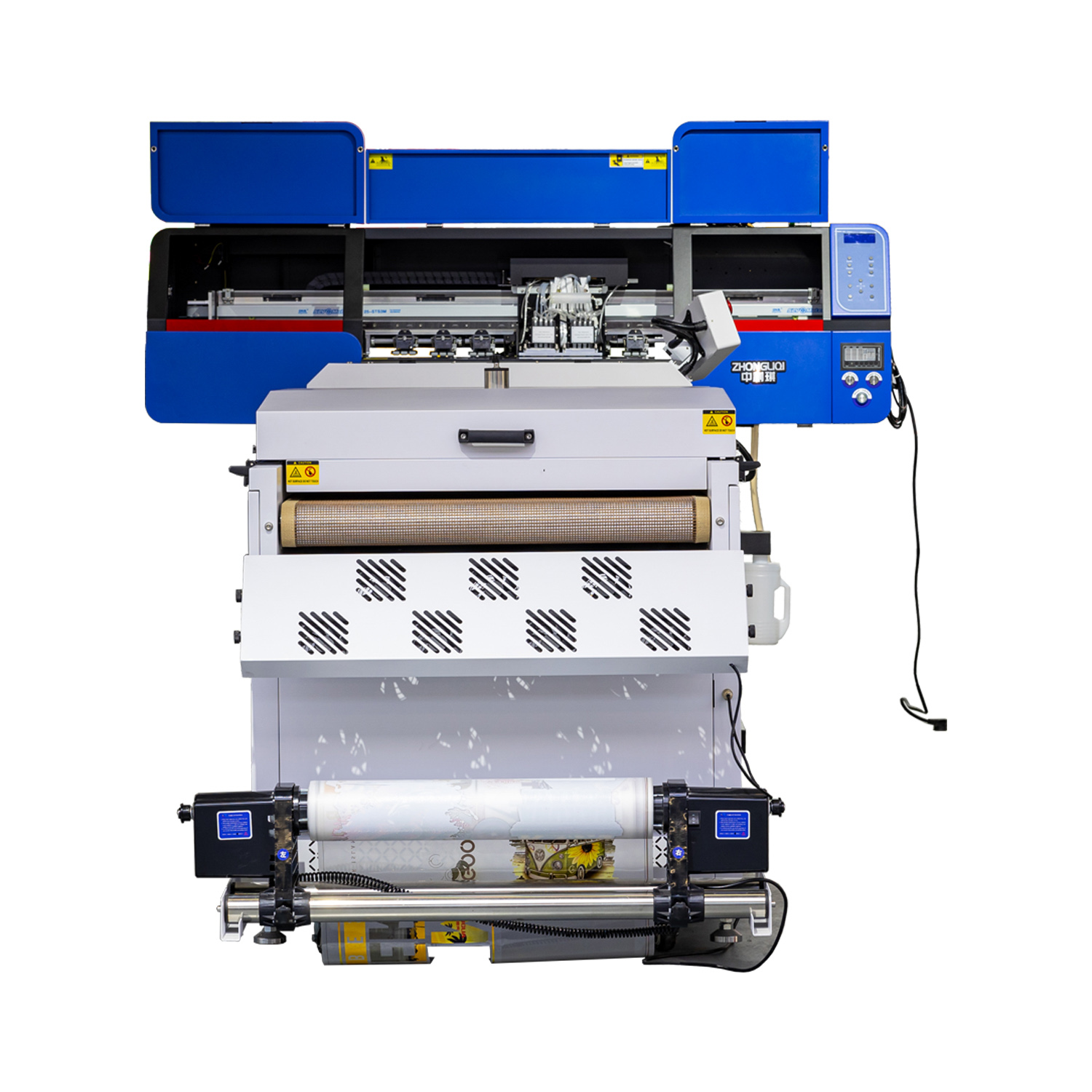

What is a UV DTF printer?

UV DTF printing is a new type of crystal label printing method. This technology requires glue, white UV DTF ink, UV varnish, etc. To cover the demolding with UV DTF film and print various patterns, then overlay them on the transfer film and perform transfer printing. Using this technology, printed design patterns can be transferred to the surface of objects. The appearance is three-dimensional, like crystal, so it is also called crystal sticker. UV DTF printed stickers can be applied to many hard surfaces and can be removed and used without any additional processes.

UV Printer and UV DTF Printer: Different Processes

In fact, UV DTF printing is a type of UV printing method, but the printing process is different: UV printers work simpler, while UV DTF printers handle more steps to take advantage.

How does a UV printer work?

UV printers can perform flatbed printing and 3D relief printing. Generally speaking, the entire printing process is divided into the following four steps: first, edit and draw the relief color area in the computer photo printing software. Secondly, add the function of white inkjet printing in the print control software. Thirdly, place the material on the UV printer platform. Finally, click on the device to start printing. When the designed pattern is printed, the entire process is completed.

How does UV DTF printer work?

There are currently two printing methods for UV DTF, one is flat printing and the other is roll to roll printing.

UV DTF flatbed printer is a traditional type of printing method.

Step 1: Tear off the A film. There is adhesive on the surface, usually A4 or A3 size, and it cannot be rolled up.

Step 2: Tear off the surface of film A to expose the adhesive surface, then arrange the adhesive surface on the flatbed printer and fix the four corners on the printer flatbed.

Step 3: Print white and then print CMYK color images.

Step 4: Use a laminating machine to cover and film the B film.

Step 5: Use a cutting device (or cut by hand or scissors) along the edges of the image.

Step 6: Take out an image from it, peel off the A film, stick the design image on the surface of the product, press back and forth with your fingers a few times, and then peel off the B film. The entire printing process is completed.

UV DTF flatbed printing is a multi-step and tedious printing method.

You can choose this printer when printing or making customized small items, as well as during the off-season market. But once there is a surge in orders or peak market season, it becomes difficult to keep up with market demand.

UV DTF roll to roll printing has much fewer steps, without the need to remove the A film surface or use a laminating machine.

Step 1: Design the pattern and draw the spot color area.

Step 2: The UV DTF printer prints directly on the A film. This A film can be placed in rolls.

Step 3: After printing the design pattern, automatically apply the film.

Step 4: Hand cut or manually transfer the pattern onto various hard material surfaces. Higher efficiency than flat printing.

The difference between UV printers and UV DTF printers

Although the two types of printers have similarities, such as UV printers and UV DTF printers both requiring the use of ultraviolet heat for printing, there are also certain differences.

Printing method

The difference between UV printers and UV DTF printers lies in the fact that UV DTF printers require more steps compared to UV printers: UV printers print directly on the substrate, while UV DTF printers first print on AB film and then attach to the substrate.