The digital textile printing industry has experienced exponential growth in the last decade. This is because more and more users, due to the ease, affordability and quality of the results, have chosen digital printers for the customization of fabrics. There are many digital printing processes for personalizing fabrics but in this article we will talk about one in particular, the latest that has established itself in a short time and is enjoying great success: the DTF printing process. Let’s take a deeper look and discover all the advantages of DTF Printer printing.

For ALL fabrics

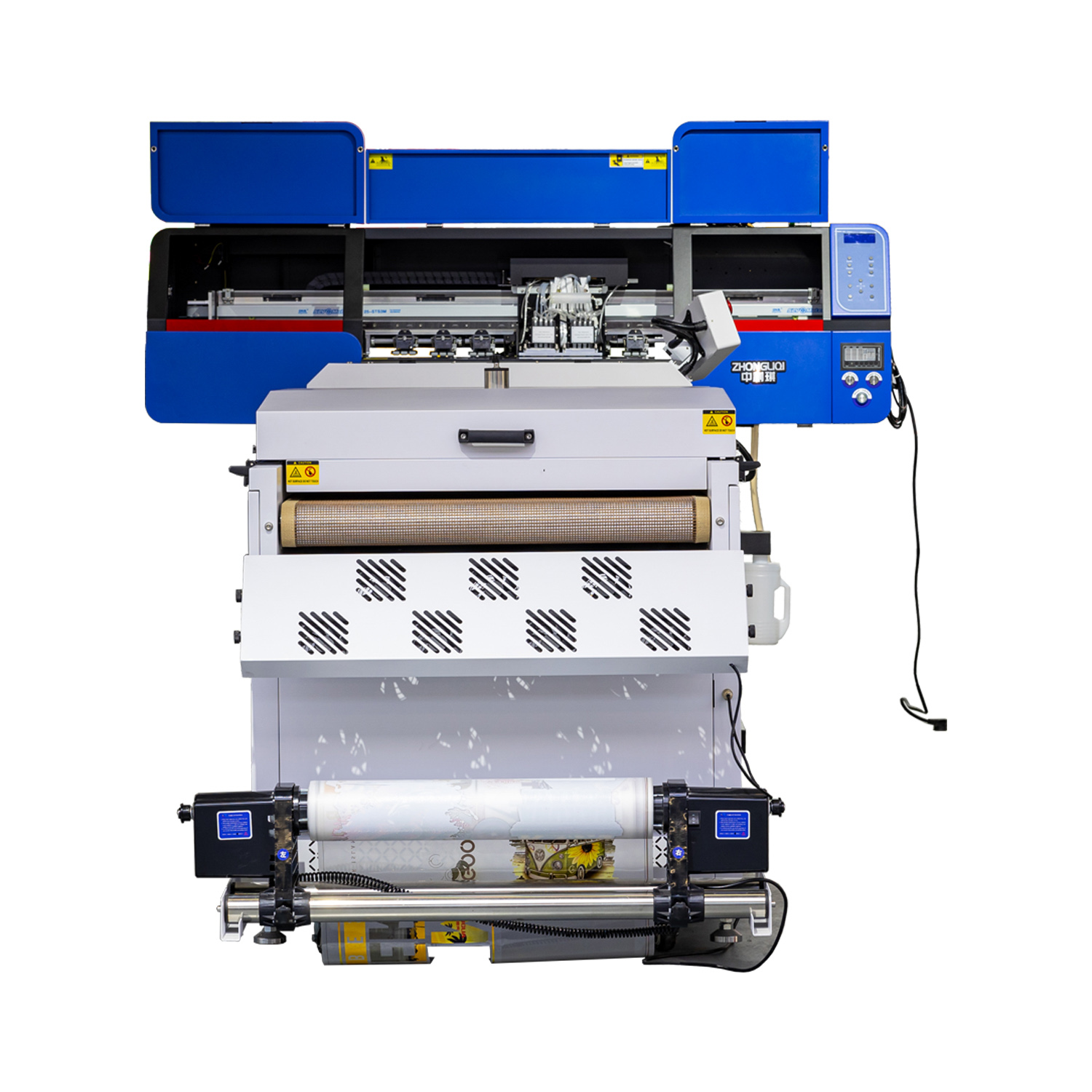

Let’s begin by answering a very common question: what is DTF printing? The answer is already contained in the acronym DTF which means Direct To Film. DTF printing consists, in fact, of direct digital printing onto PET transfer films which are then heat transferred onto the fabrics.

On which fabrics? All fabrics. And this is exactly the main reason for its success. With DTF printing you are free to customize any type of fabric. Whether natural, synthetic or mixed fabrics, there is no limit whatsoever, you just need to use the right heat melting powder glue for each type of fabric. Furthermore, in DTF printing, fabrics do not require any pre-treatment before being personalized and this also applies to a very delicate support such as natural leather and therefore makes it preferable to another very common technology: DTG (Direct To Garment) printing in which the printing takes place directly on the fabrics but requires that the fabrics are pre-treated, with a considerable waste of time.

A SINGLE transfer film for all customizations

Yes, with a single transfer film it is possible to customize all fabrics. And this is thanks to the intrinsic feature of DTF technology, which uses textile pigment inks and a high-performance thermoadhesive powder glue which combined guarantee excellent coverage of the transfer film on both light and dark colored fabrics of different types. Whether we are talking about cotton, polyester, denim, leather, mixed fibres, there is only one product to use. It is a matt/matt PET transfer film available both in sheets and in reels with excellent transfer characteristics. It is advisable to choose a transfer film with European origin to guarantee excellent performance. Another benefit of the DTF transfer film is that it is suitable for all DTF printing systems, therefore both for plotters and printers, … and it also integrates perfectly into DTG printing systems.

Transfer film low production costs

Another advantage of DTF printing is the cost-effectiveness of the entire process required to produce the ready-to-transfer film, compared to other printing technologies. As a matter of fact, the cost of printing is low, so as the transfer film itself and the thermoadhesive powder glue application process.

High color quality

DTF printing has an ace up its sleeve that makes it unique and preferable compared to other printing technologies: it guarantees unparalleled color quality. This is because of ink-jet technology which prints at a very high resolution and DTF inks which do not sink into the fibers of the fabric, but remain on the surface resulting in sharp images and very vibrant, bright colours. Added to this is also the possibility of using fluorescent colors (optional) which make the printing results on all fabrics truly surprising.

Soft and wash-resistant prints

The high printing quality is combined with the softness of the transferred images. This is great added value and finally, another important feature of DTF printing: resistance to washing up to 60°C.

The advantages of DTF printing don’t finish here. In fact, compared to other technologies, it guarantees lower white consumption (limited to 40%) and quicker and simpler production. Furthermore, it does not require advanced printing skills and represents an optimal solution even for small production cycles and batches.