The development of DTG ink has gone through the following stages:

Early exploration stage (1950s - 2004):

Origin of inkjet technology: In the 1950s, experts began to develop inkjet printer technology, which is the foundation for the development of DTG ink technology. At that time, inkjet technology was mainly applied to paper printing, but it also provided technical ideas for later applications on textiles.

Advancement of technology research and development: In the following decades, inkjet technology continued to develop and improve. Researchers were constantly exploring the possibility of applying inkjet technology to fabrics. However, at this stage, due to technical limitations, direct inkjet printing on fabrics faced many challenges, such as ink easily clogging the nozzle and poor adhesion of ink on fabrics, making it difficult for this technology to be widely used in the field of garment printing.

Initial birth stage (2004 - 2005):

Launch of prototypes: In 2004, at the Specialty Graphic Imaging Association (SGIA) exhibition held in Minneapolis, two companies, U.S. Screens and Mimaki of Japan, respectively launched prototypes of DTG printers. U.S. Screens' T-Jet was improved from a Japanese-designed printer that can print on 3D objects (such as wooden blocks); Mimaki launched the GP - 604. The appearance of these two prototypes marked the official entry of DTG technology into the field of garment printing, but at this time the technology was not mature enough and there were still some problems.

White ink breakthrough stage (2005 - 2006):

Research and development of white ink: Before 2005, DTG printing had poor effects on dark fabrics due to the lack of white ink. In this year, U.S. Screen Company cooperated with an ink manufacturer to develop white ink. As a pretreatment process, white ink is printed on dark fabrics first as a white base color, and then color patterns are printed on it, greatly improving the printing effect of DTG on dark fabrics.

Initial promotion of technology: In November 2005, the research and development of white ink was completed, and U.S. Screen Company obtained an exclusive one-year contract for using this ink. In 2006, white ink began to be gradually opened to other manufacturers. This breakthrough further promoted the application of DTG technology in the garment printing industry.

Technology improvement stage (around 2009):

Printer improvement: In 2009, modern DTG printers such as the Viper DTG printer were launched. These printers have greatly improved in terms of printing speed, printing quality, and equipment stability, laying a foundation for the wide application of DTG technology. For example, the increase in printing speed enables DTG printing to meet the production needs on a larger scale, and the improvement in printing quality makes the printed patterns clearer and the colors more vivid.

Diversified development stage (from 2010 to present):

Improvement of ink performance: With the continuous progress of technology, the performance of DTG ink continues to improve, including color vividness, washing fastness, and ink stability. For example, after several years of testing and improvement, the color vividness of digital pigment printing ink has reached the level of reactive ink, and it has also greatly improved in washing fastness.

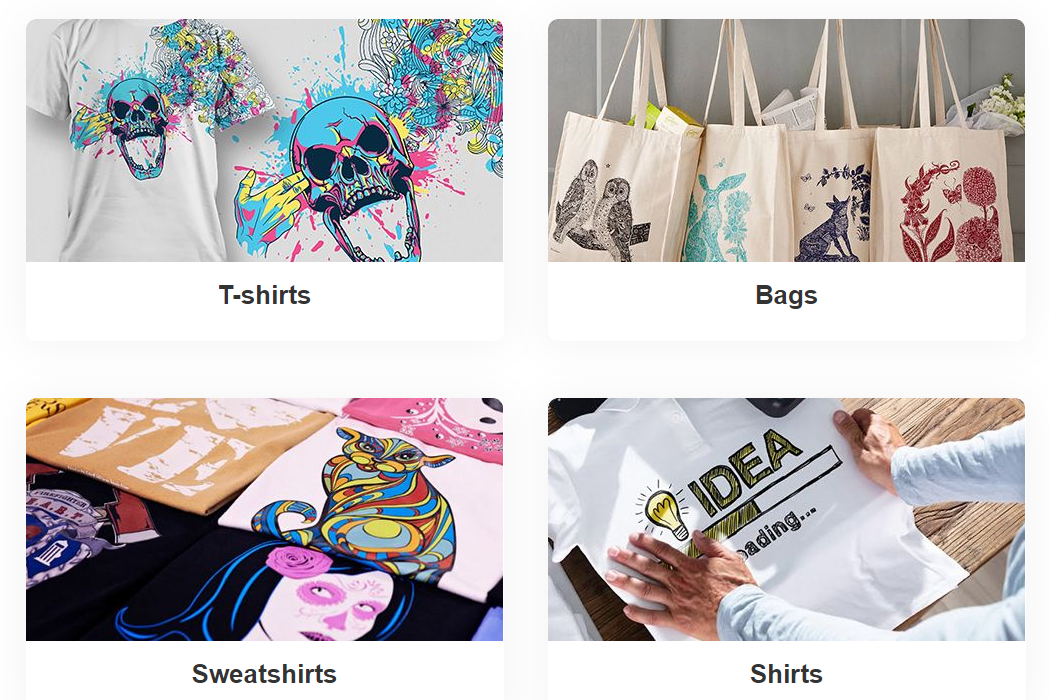

Expansion of application fields: DTG technology is not only applied to garment printing but also gradually expands to other fields, such as home textile printing and personalized gift customization. At the same time, related supporting equipment and software for DTG technology are also constantly developing and improving, making the entire DTG printing industry chain more mature and complete.