How to improve printing quality?

I. Optimize printing equipment

Printhead maintenance and calibration

Cleaning the printhead: Regular cleaning of the printhead is the key to maintaining good printing quality. As the number of printings increases, impurities such as ink residue and dust may clog the printhead. You can use the cleaning program that comes with the printer for cleaning. For severely clogged cases, you may need to use a special printhead cleaning solution. For example, when stripes or color - missing problems are found in printing, the first thing to consider is whether the printhead is clogged, and timely cleaning can restore the normal ink - ejection function of the printhead.

Calibrating the printhead: Printhead calibration ensures that ink - dots are ejected accurately at the predetermined positions. Many printers have a printhead calibration function, which allows you to print calibration patterns and make adjustments according to the printer's prompts. During calibration, pay attention to the horizontal and vertical positions of the printhead to ensure the accuracy of the printed pattern and avoid ghosting or blurring.

Checking the printhead status: Regularly check the wear condition of the printhead. If the nozzles of the printhead are worn, the size and ejection direction of ink - drops may be affected. During the printing process, if it is found that the printing quality is gradually declining and there is no improvement after cleaning and calibrating the printhead, it may be necessary to replace the printhead.

Color management

Color calibration: Use professional color - calibration tools to calibrate the printer's colors. These tools can measure the colors output by the printer and compare them with standard colors, and then generate color profiles to adjust the printer's color output. For example, when printing photos or design works, accurate color calibration can ensure that the printed colors are as close as possible to the colors displayed on the screen.

Choosing the appropriate color mode: Select the appropriate color mode according to the printing content and purpose. For example, the RGB mode can provide more vivid colors for photo printing; while the CMYK mode is more suitable for commercial printing because it matches the colors of printing inks. In some professional graphic software, the color mode of the image can be converted to a mode suitable for printing to improve printing quality.

Updating printer firmware and drivers: Printer manufacturers often release updates for firmware and drivers, which may include improvements in color management. Timely updates can optimize the printer's color - output performance, improve printing quality, and may also fix some known printing problems.

Mechanical - structure adjustment

Checking the paper - feeding mechanism: Ensure that the paper - feeding mechanism works properly and the paper can pass through the printing area smoothly and at a constant speed. If the paper - feeding is jammed or skewed, it will affect the printing quality. You can clean the dust and debris in the paper - feeding channel, check whether the paper - feeding rollers are worn, and replace them if necessary.

Adjusting the flatness of the printing platform (for flat - bed printers): For flat - bed printers, ensure the flatness of the printing platform. You can use a level to check whether the platform is level and adjust the feet of the platform to make it level. When printing three - dimensional objects or thick media, ensure that the distance between the printhead and the medium surface is appropriate to obtain a uniform printing effect.

II. Select appropriate printing media

Select media types according to printing content

Paper: If you are printing documents, ordinary copy paper can meet basic requirements. However, if you are printing photos, it is best to choose glossy or matte photo paper to achieve better color reproduction and gloss. For label printing that requires waterproof and oil - proof properties, synthetic paper or waterproof label paper can be used.

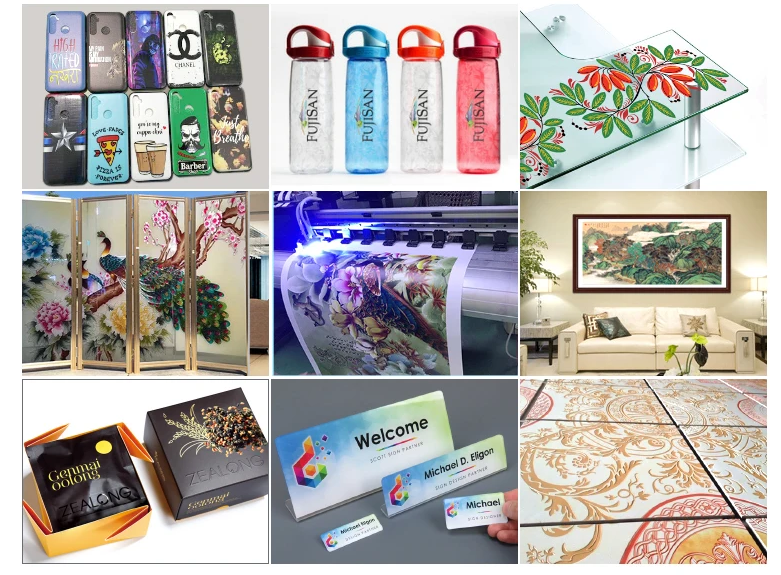

Other materials: When printing on non - paper materials such as fabric, plastic, and metal, select appropriate inks and printing methods according to the characteristics of the materials. For example, when printing on fabric, use inks suitable for fabric and

Related Product :